Energy Efficiency Standards and Marking Methods of the Energy Conservation Label for Dryers were revised and became effective on November 20, 2013.

Energy Efficiency Standards and Marking Methods of the Energy Conservation Label for Dryers was announced with document number Neng-ji-zi No. 10205019631 and became effective on November 20, 2013.

I. To apply for certification of the energy conservation label for dryers, the energy efficiency test conditions and methods, as well as energy efficiency standards, should comply with the following regulations:

(1) Test conditions:

1. The ambient temperature should be at 20℃±2℃ and the relative humidity should be 65±5%.

2. The materials and specifications of the test fabric are as follows:

(1) Material: cotton gauze fabric

(2) Mass density: 100±10g/m2

(3) The density of warp and weft is 30±2 threads/cm x 27±2 threads/cm.

(4) The coarseness of warp and weft is 32±2S × 36±2S.

3. Size specifications and de-sizing of the test fabric:

(1) Size specifications of the test fabric are as shown in the following figure (unit: mm):

(2) De-sizing of new test fabric is as shown in the following table; it has to be performed four times in a row. The test fabric cannot be used when its weight reduces to less than 90% after being repeatedly used.

| Step | Time (min) | Condition |

| Wash | 10 | Don’t put detergent in |

| Spin | 2 | |

| Inject water and wash | 2 | Water injection speed 15L/min |

| Spin | 2 | |

| Inject water and wash | 2 | Water injection speed 15L/min |

| Spin | 5 | |

4. Weight of the test fabric:

(1) Place the very dry test fabric in an environment where the ambient temperature is at 20±2℃ and the relative humidity is 65±5% for 24 hours. After that, take the test fabric with the same weight as that indicated by the dryer for subsequent tests.

(2) The marked value of the dryer divided by 1.08 is the weight of the very dry test fabric to be taken, whereby there is no need to place the very dry test fabric in an environment where the ambient temperature is at 20±2℃ and the relative humidity is 65±5% for 24 hours.

(3) “Very dry” is defined as drying the test fabric at the maximum temperature indicated by the dryer for at least 10 minutes. After taking it out to measure its weight, dry the test fabric for another 10 minutes until its weight change is within 1%.

5. Accuracy of instruments:

(1) Thermometer: within ±0.5℃ (0~50℃).

(2) Wattmeter: within ±0.5%.

(3) Watt-hour meter: within ±0.5%, with a resolution of within 1Wh.

(4) Chronograph: within ±0.5s/h.

(5) Weight scale: within ±0.3% (1~10kg), with a resolution of within 0.5g.

(2) Test steps:

Step 1: Place large test fabric first, and lastly use small test fabric for minute adjustments to reach the marked volume. The volume tolerance is within ±0.5%.

Step 2: Soak the test fabric in water at room temperature for more than 15 minutes to have it saturated.

Step 3: Put the test fabric into the spin dryer and spin it at a rate of 60.0±2.0%.

Step 4: Put the test fabric into the dryer drum after it was spun, set the time as the maximum heating time, and start drying the test fabric. If the dryer is an automatic stop type with a temperature or humidity sensor, set the heating time according to the operating instructions.

Step 5: Record power consumption (W) shown on the wattmeter and heating time. Also, record electricity consumption (kWh) shown on the watt-hour meter until reaching the heating time (excluding cooling time) or automatic stop. Stop the dryer and take the test fabric out to measure its weight.

Step 6: Calculate the drying rate; it should be within 95.0±2.0%, otherwise you should shorten the drying time or extend the hearing time. Repeat steps 2-5.

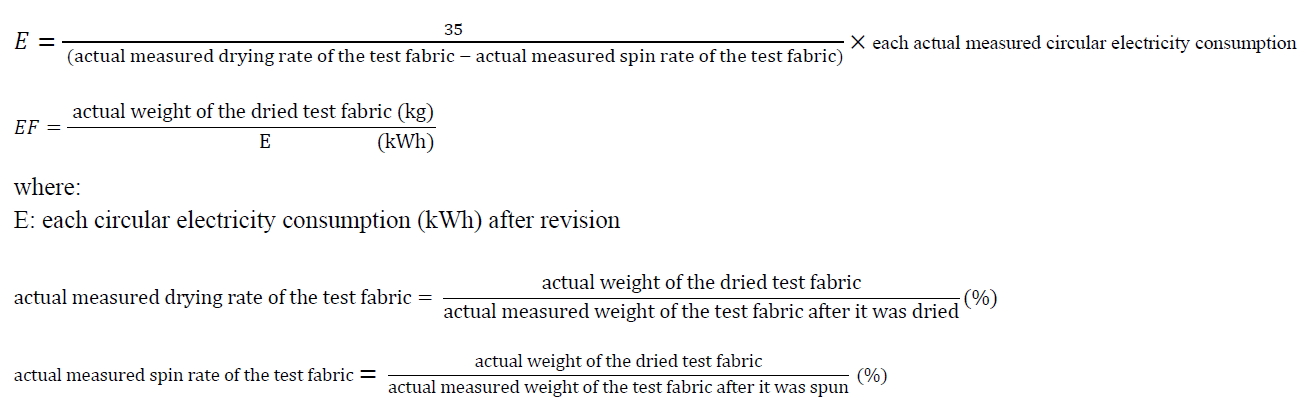

(3) Energy efficiency standards: The energy factor (EF) should be greater than 1.71kg/kWh. The equation for calculating EF is as follows:

II. Attention should be paid to the following concerning the energy conservation label’s energy efficiency marking:

(1) The name and address of the user must be clearly marked on the product or package. If the user is an agent, the name and address of the manufacturer must be clearly marked on the product or package as well.

(2) The nameplate should display the drum volume of the product, and the product catalog should display the EF of the product.

(3) The product’s actual measured energy factor (EF) should be calculated to the second decimal point. The third decimal point should be rounded up.